BRINGING PUMP ENGINEERING SOLUTIONS TO YOU

Your Pump Application Needs Solved For You

- UL Listed

- Made in the United Kingdom

- Backed by 40 years of service and experience

- Global availability and scope

- Fast shipping time

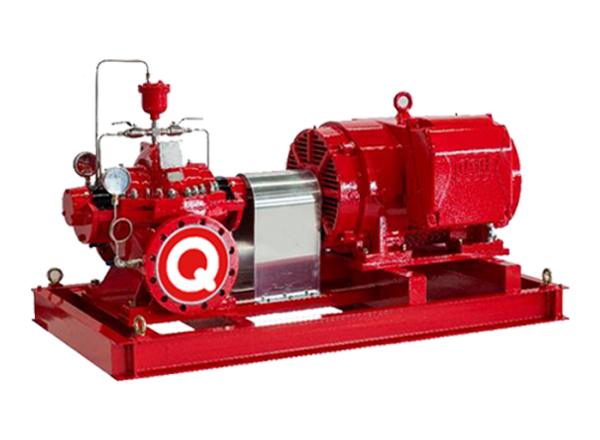

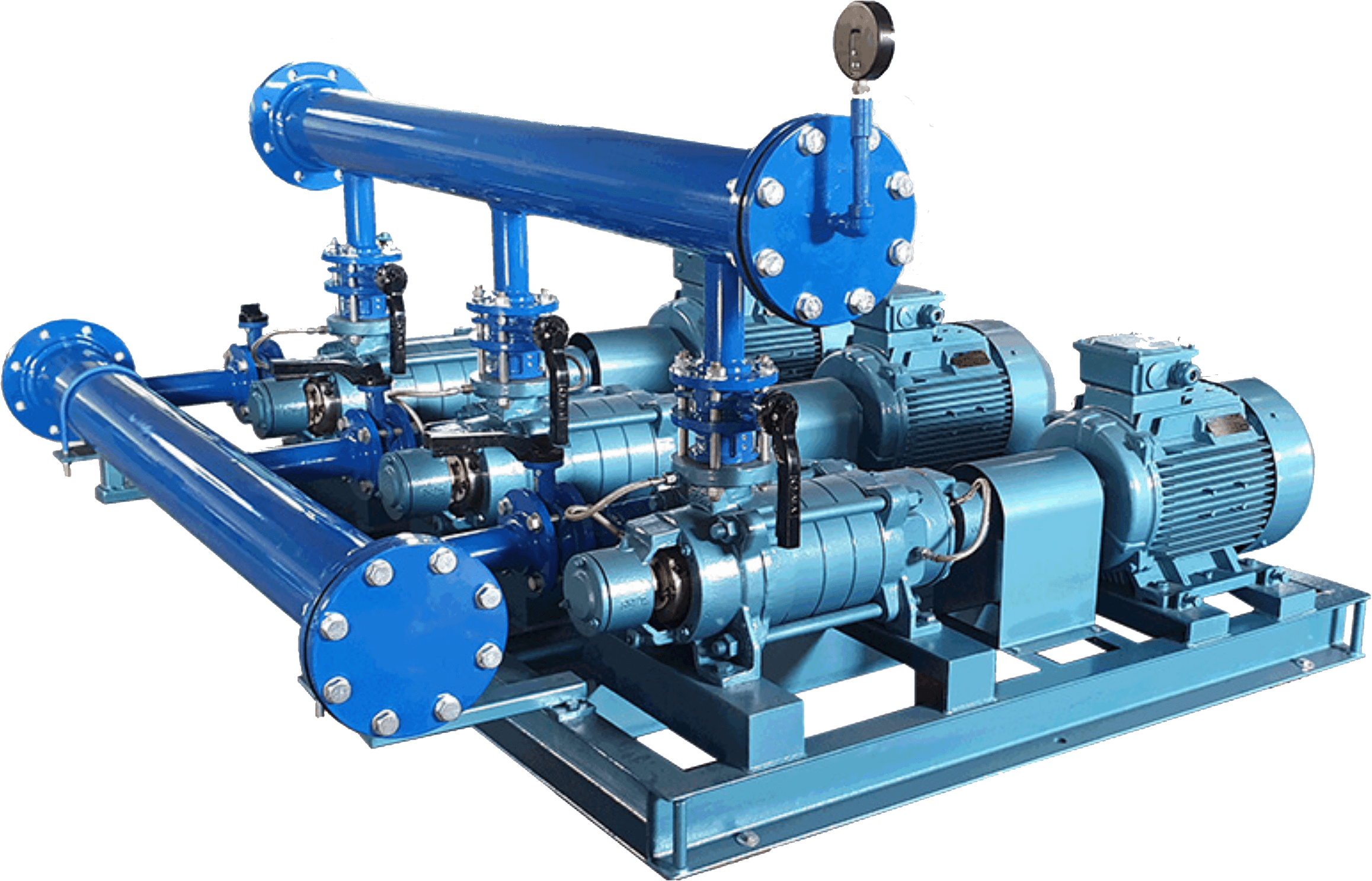

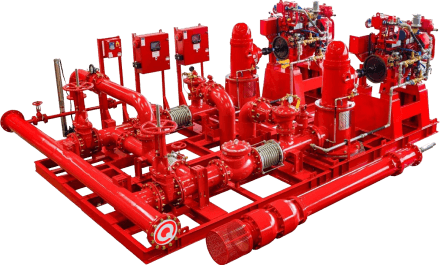

Quantum Fire Sets

All fire sets are designed and manufactured in accordance with NFPA 20 and UL listed in full up to a capacity of 8000 US gpm.

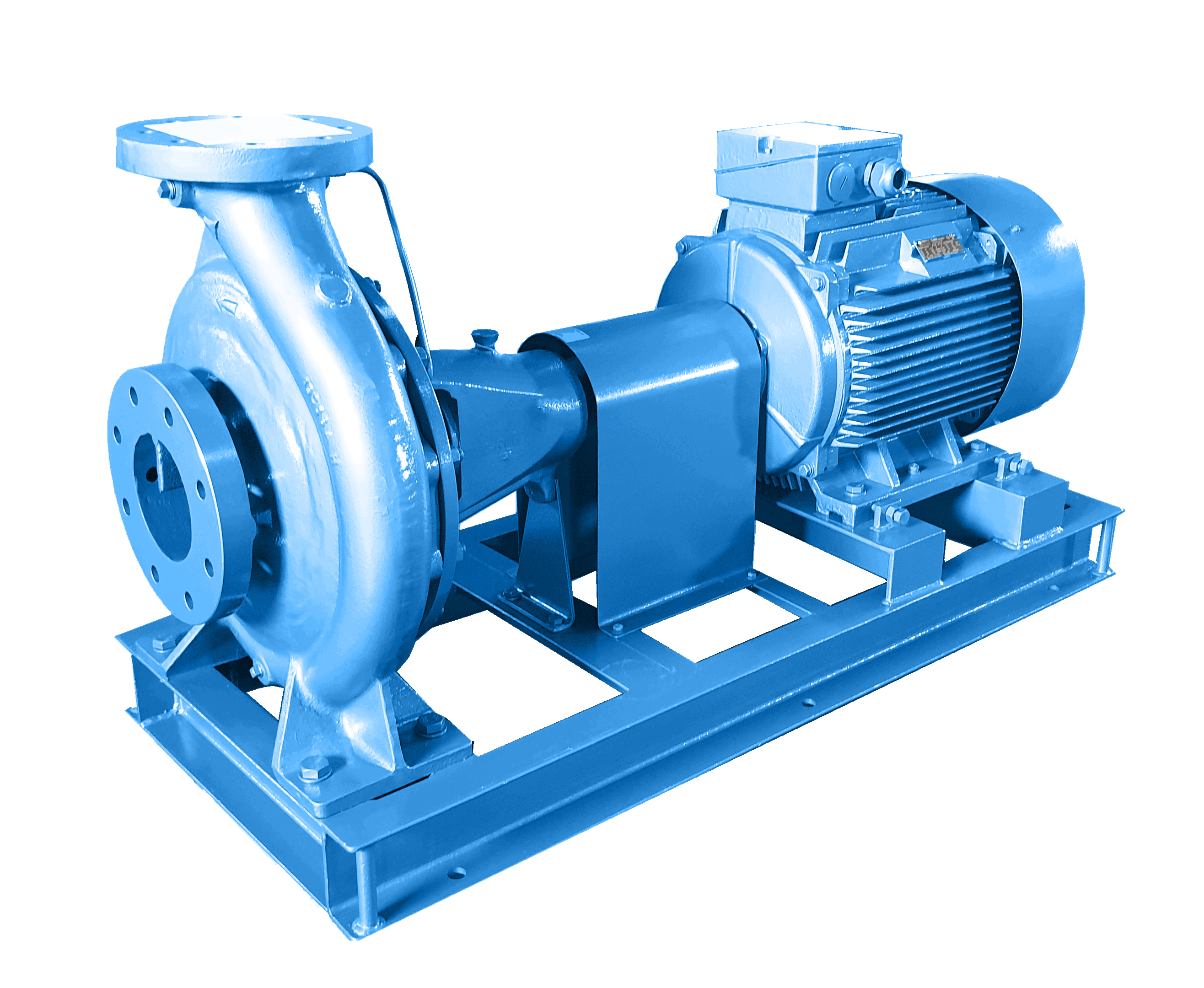

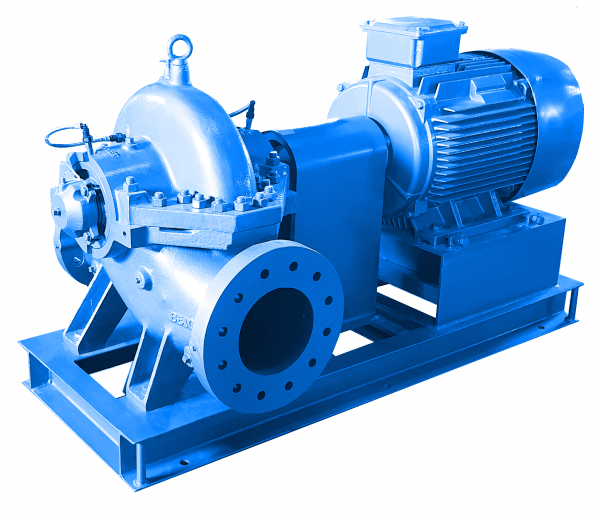

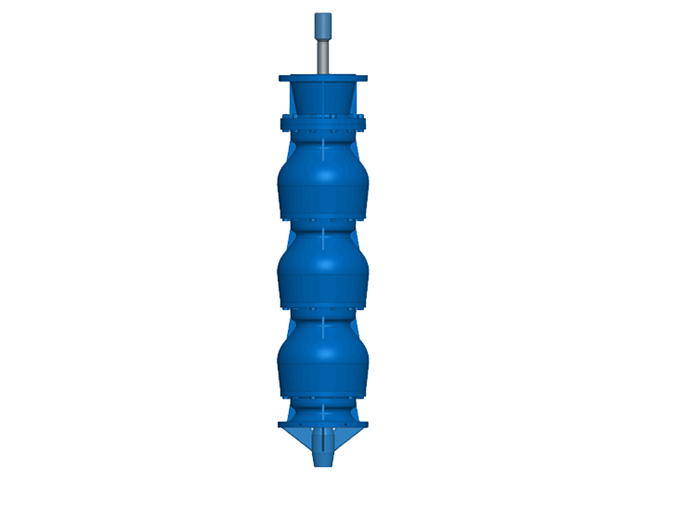

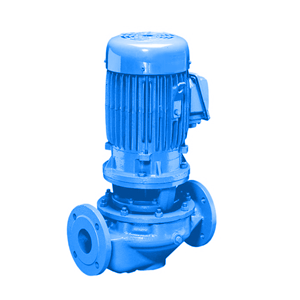

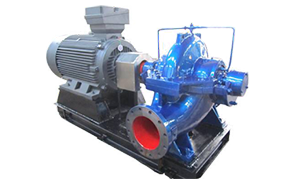

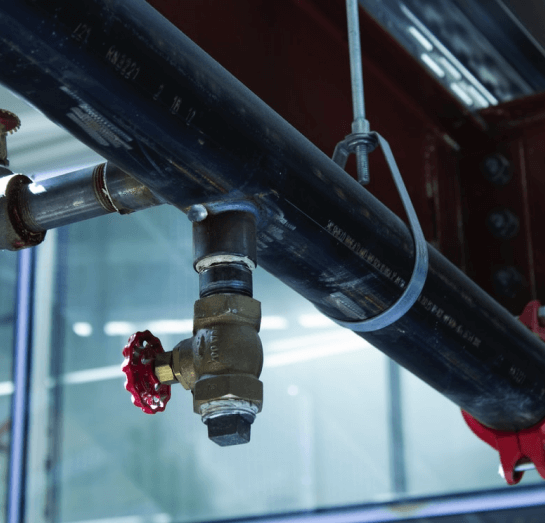

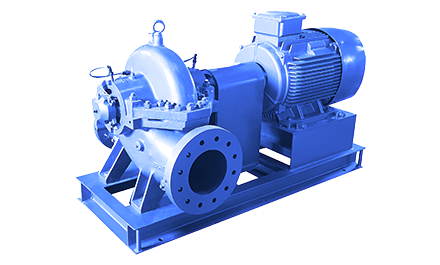

Quantum Water Pumps

Double Suction, Single or Double Stage, Axially Split Case, Electric Motor or Engine Driven, Horizontally or Vertically Mounted Centrifugal Pumps.

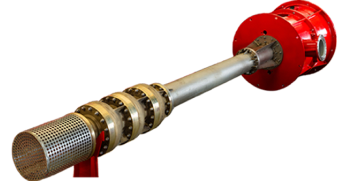

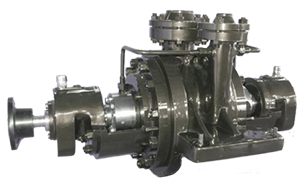

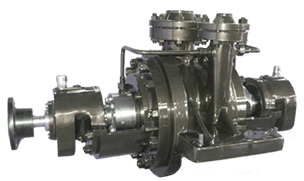

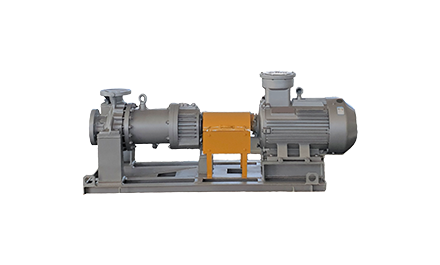

Quantum Oil & Gas Pumps

Robust, reliable, long endurance life and manufactured in accordance with APO 610 standards and engineered with unique mechanical construction